Effectively applying computer vision in the industrial production process can guarantee that your company achieves more assertive results with quality and speed.

Due to its differentials, this is one of the areas of artificial intelligence that stands out the most in the market. However, to know how to take advantage of this intelligence in the best possible way, first, it is necessary to understand how to apply it and its participation in production.

Want to find out how this technology can change your business? So keep following the article, and happy reading!

The Application Of Computer Vision In The Industry

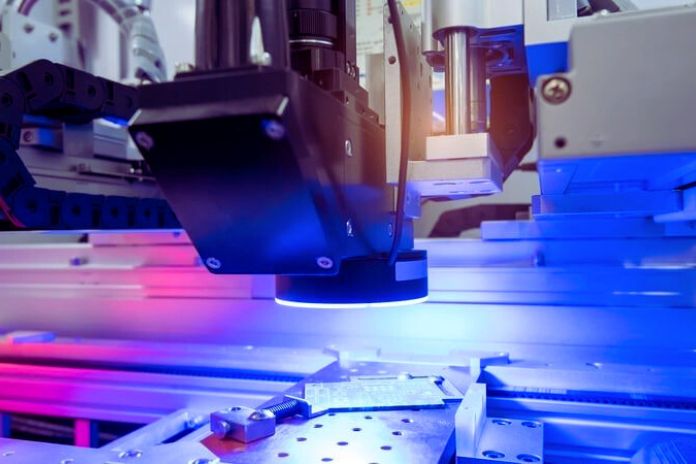

When we talk about the application of computer vision in the industrial production process, it is impossible not to look at the optimization part.

After all, one of the reasons that led the technology to become a major trend and gain market evidence is its high precision, speed, and repeatability when applied to quantitative processes.

The approach is so impressive that several enterprises already recognize the importance of Machine Vision – machine vision system – in their realities.

Examples Of Applications

Different ways to apply computer vision in the industry in different business models exist. Therefore, we highlight below some examples of the main applications of this technology. Starting with:

Operational Safety

Security is one of the most important aspects for any business, and looking for increasingly effective processes that offer greater security is essential for any business that wants to remain active for a long time.

With the implementation of computer vision, the possibility of obtaining more accurate and reliable information becomes a reality.

Technology makes it possible to improve decision-making based on information obtained from the environment where the vision system was implemented, ensuring data integrity.

Another positive point is the security offered to your team. Depending on the installed system, alerting your employees when an activity is being performed incorrectly, avoiding problems with the product or service, and possible exposure to life-threatening situations is possible.

Quality Inspection

Quality analysis of the final product produced is one of the main applications of computer vision in the industrial production process. Although its value is greater in industrial environments, for example, one cannot ignore the capacity for qualitative control in any business.

Comparisons made by computer vision make it possible to discover whether your product or service is following the standards it must meet in a very short time.

And yet, if they are not in compliance, detailed data can be displayed, allowing you to solve problems more quickly.

Generally, quality control done through computer vision is applied to:

- Dimensional control of manufactured parts;

- Feature count, compared to market standards or nationally or internationally established rules;

- Identification of anomalies.

How It Works

It can be said that computer vision in the industrial production process works simply. Technology has been used as a basis for innovation in numerous segments. From games to autonomous cars, you will hardly find a scenario where it is impossible to apply it.

By using on-site technology equipment, such as cameras, for example, it is possible to detail which people and objects are present in a given scenario and even say who these people are and what they are doing.

The technology works as a vision, allowing machines to assimilate what is happening in their environment.

Based on what is collected, processing algorithms are used so that the machine can make intelligent decisions based on what is happening in the environment.

This whole process consists of three steps:

- Image acquisition: through cameras, sensors, or image capture devices, the machines can “see” the environment where they are;

- Image pre-processing: before the obtained image can be analyzed, it needs to be pre-processed to remove noise and improve the quality of what is being received. This step may include filters, contrast normalization, and color correction, among other techniques;

- Image analysis: pre-processed images are analyzed to extract relevant data, such as edges, shapes, textures, etc. This feature detects objects, recognizes patterns, performs measurements, and performs other tasks.

Why Should You Invest In Computer Vision?

Being well-known in the industry, large companies already successfully apply this technology. However, its high cost of implementation was an entry barrier for many enterprises, requiring several assessments and studies to discover the feasibility of the implementation project, thus noting the numerous advantages that could be obtained, such as reducing basic costs simultaneously.

That offers great performance is desired by practically every company. With the advancement of technologies and development based on increasingly elaborate software, it has provided a reduction in implementation costs.

Acquiring a computer vision system proves to be a true competitive advantage. The benefits you get are so great that your company can start taking big steps ahead of the competition.

Invest In Digital Solutions Today!

As we can see, computer vision in the industrial production process can change the reality of a business, being the perfect solution for anyone who wants to take that extra step – and safely towards success.

Also Read: Service via WhatsApp: 4 Tips On How To Do It